TCB10 Self-Lubricating Multilayer Composite Bushing

Structure Characteristics and Applications

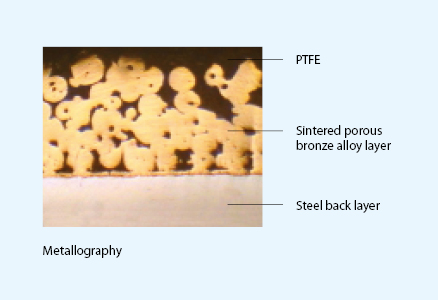

TCB100 is backed with copper-plated steel with porous bronze sintered on the steel and polymers (PTFE) imbedded into the bores of the bronze. By combining the metals and the polymers together, its products are endowed with the lower friction coefficient and good capacity of anti-abrasion and self-lubrication. Moreover, the steel back is plated with an erosion-prevention layer. Products of TCB 10 series are widely applied in printing, textile and tobacco machinery, gymnastic equipments, etc.

Technical Data

Technical Data

| Performance Index | Data | |

| Max Load P | Static Load | 250N/mm? |

| Dynamic Load | 140N/mm? | |

| Oscoillation Load | 60N/mm? | |

| Linear Velocity V | Dry Lubrication | 2.5m/s |

| Oil Lubrication | >5m/s | |

| Max PV value | Grease Lubrication | 1.8N/mm? .m/s |

| Oil Lubrication | 3.6N/mm? .m/s | |

| Friction Coefficient | Dry Lubrication | 0.08~0.20 |

| Oil Lubrication | 0.02~0.07 | |

| Mating Axis | Hardness | >200 HB |

| Roughness | Ra=0.4~1.25 | |

| Working Temperature | -200~+280℃ | |

| Heat-conducting Coefficient | 40W/(m·k) | |

| Heat-expansion Coefficient(Axial) | 11×10-6/K | |

Anti-abrasion Performance

Anti-abrasion Performance

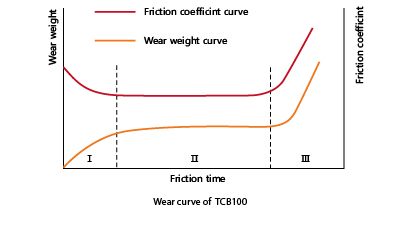

2. "Stabilization" abrasion phrase: After the "Running-in" phase, the friction happens between PTFE and PTFE, thus the friction coefficient is smaller and keeps steady. As a result, the wear rate is low and steady. See the curve showed in areaⅡof the graph.

3. "Sharp" abrasion phrase: As PTFE in the porous layer is slowly consumed up, not enough lubricant can be supplied to the gliding media. Friction coefficient and wear rate will rapidly rise. When 70% of the bronze surface is exposed, service life of TCB100 closes to its end. See the curve showed in area Ⅲof the graph.

Main Factors that Influence the Service life of the Bushing

Main Factors that Influence the Service life of the Bushing

1).PV ValuePV value is an effective criterion to calculate the service life of TCB100. If there is need to prolong the service Life, PV value must be reduced.

2).Environment Temperature

The higher the working temperature is, the shorter the life of the products would be.

3).Quality of the Mating Surface

Service life of TCB100 can be obviously prolonged if its mating axis is made by alloy steel or is plated by hard chrome and with surface Roughness Ra=0.4~0.63.

Besides the standard products displayed in the list of this catalogue, we can also supply non-standard products or develop according to customer design.

TCB10 Classification

-

TCB 100

Its material structure is Steel base + Bronze powder + PTFE and filler. It can offer the good properties of self-lubricating, anti-abrasion, low-friction, fully developing the advantages of metal and multi-element polymer. It’s applied to the printing, woven, tobacco and gymnastic machinery, etc.

-

TCB 101

Its material structure is Bronze base + Bronze powder + PTFE and filler. It can offer the good properties of self-lubricating, anti-abrasion, low-friction, fully developing the advantages of metal and multi-element polymer. The product is applied to metallurgical industry, continuous casting and rolling mill...

-

TCB 102

Its material structure is Stainless steel base + Bronze powder + PTFE and filler. It can be used in strong acid and alkaline. It’s applied to the corrosion resistant part in dyeing machinery and ocean industry, etc.

-

TCB 103

Its material structure is Steel base + Bronze powder + PTFE and filler. This product is developed according to the high PV value of hydraulic pump. It can offer the low friction coefficient and good anti-abrasion. It can be used in semi-dry condition. This product is applied to medium and high pressure gear ...

-

TCB 104

Its material structure is Steel base + Bronze powder + PTFE and filler. This product is developed according to reciprocating motion of shock absorber and high pressure in flank. It can offer low friction coefficient and good anti-abrasion. It’s used in semi-dry condition. The product is applied to shock absorber of ...

Product Classification

TCB10 Self-Lubricating Multilayer Composite Bushing TCB20 Boundary Lubricating Bushings TCB30 Bimetal Bushing TCB40 Oil Sintered Bearing TCB50 Solid Lubricating Bearing TCB60 Steel Bearings TCB70 Spherical plain bearing TCB80 Casting Bronze Bearing TCB90 Wrapped Bronze Bearing TCB-21 Filament Wound High Load Self-lubricating Bearings